Which of the Following Best Explains Why a Colorful Tulip Is Not Typically Viewed as a Work of Art

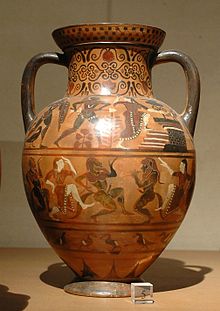

Etruscan: Diomedes and Polyxena, from the Etruscan amphora of the Pontic group, c. 540–530BCE – From Vulci

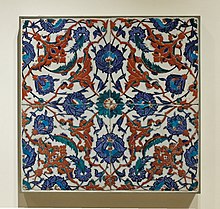

16th century Turkish Iznik tiles, which would have originally formed part of a much larger grouping

Ceramic art is fine art made from ceramic materials, including clay. It may take forms including creative pottery, including tableware, tiles, figurines and other sculpture. As one of the plastic arts, ceramic art is i of the visual arts. While some ceramics are considered fine fine art, such equally pottery or sculpture, virtually are considered to exist decorative, industrial or practical fine art objects. Ceramics may also exist considered artefacts in archæology. Ceramic art can exist made by 1 person or by a group of people. In a pottery or ceramic factory, a group of people blueprint, manufacture and decorate the art ware. Products from a pottery are sometimes referred to as "art pottery".[1] In a ane-person pottery studio, ceramists or potters produce studio pottery.

The discussion "ceramics" comes from the Greek keramikos (κεραμεικός), pregnant "pottery", which in turn comes from keramos (κέραμος) meaning "potter's clay".[2] Most traditional ceramic products were made from clay (or clay mixed with other materials), shaped and subjected to heat, and tableware and decorative ceramics are generally however fabricated this way. In modern ceramic applied science usage, ceramics is the art and science of making objects from inorganic, not-metallic materials by the action of rut. It excludes glass and mosaic made from drinking glass tesserae.

There is a long history of ceramic fine art in almost all developed cultures, and ofttimes ceramic objects are all the artistic prove left from vanished cultures, like that of the Nok in Africa over two,000 years ago. Cultures especially noted for ceramics include the Chinese, Cretan, Greek, Persian, Mayan, Japanese, and Korean cultures, as well every bit the modern Western cultures.

Elements of ceramic art, upon which unlike degrees of emphasis take been placed at unlike times, are the shape of the object, its decoration by painting, carving and other methods, and the glazing found on most ceramics.

Materials [edit]

Dissimilar types of dirt, when used with dissimilar minerals and firing atmospheric condition, are used to produce earthenware, stoneware, porcelain and bone china (fine china).

- Earthenware is pottery that has not been fired to vitrification and is thus permeable to h2o.[3] Many types of pottery accept been made from it from the earliest times, and until the 18th century it was the most common type of pottery outside the far East. Earthenware is often made from clay, quartz and feldspar. Terracotta, a type of earthenware, is a clay-based unglazed or glazed ceramic,[iv] where the fired trunk is porous.[5] [six] [seven] [8] Its uses include vessels (notably bloom pots), h2o and waste product h2o pipes, bricks, and surface embellishment in building construction. Terracotta has been a common medium for ceramic fine art (see below).

- Stoneware is a vitreous or semi-vitreous ceramic made primarily from stoneware clay or non-refractory burn down dirt.[9] Stoneware is fired at high temperatures.[10] Vitrified or not, it is nonporous;[11] it may or may non exist glazed.[12] Ane widely recognised definition is from the Combined Nomenclature of the European Communities, a European manufacture standard states "Stoneware, which, though dense, impermeable and hard enough to resist scratching past a steel point, differs from porcelain because it is more opaque, and normally just partially vitrified. It may be vitreous or semi-vitreous. It is usually coloured grey or brownish considering of impurities in the clay used for its industry, and is usually glazed."[11]

- Porcelain is a ceramic textile made past heating materials, generally including kaolin, in a kiln to temperatures betwixt 1,200 and 1,400 °C (2,200 and two,600 °F). The toughness, strength and translucence of porcelain, relative to other types of pottery, arises mainly from vitrification and the formation of the mineral mullite within the torso at these high temperatures. Properties associated with porcelain include low permeability and elasticity; considerable strength, hardness, toughness, whiteness, translucency and resonance; and a loftier resistance to chemical attack and thermal shock. Porcelain has been described as beingness "completely vitrified, hard, impermeable (fifty-fifty before glazing), white or artificially coloured, translucent (except when of considerable thickness), and resonant". Nonetheless, the term porcelain lacks a universal definition and has "been practical in a very unsystematic fashion to substances of various kinds which take merely sure surface-qualities in common".[thirteen]

- Bone red china (fine prc) is a blazon of soft-paste porcelain that is equanimous of bone ash, feldspathic material, and kaolin. Information technology has been defined as ware with a translucent torso containing a minimum of thirty% of phosphate derived from creature bone and calculated calcium phosphate.[11] [ clarification needed ] Developed by English potter Josiah Spode, os mainland china is known for its high levels of whiteness and translucency,[14] and very high mechanical strength and chip resistance.[fifteen] Its high force allows it to be produced in thinner cross-sections than other types of porcelain.[fourteen] Like stoneware it is vitrified, but is translucent due to differing mineral properties.[16] From its initial development and up to the later office of the twentieth century, bone red china was well-nigh exclusively an English product, with production being effectively localised in Stoke-on-Trent.[xv] Most major English firms made or still brand information technology, including Mintons, Coalport, Spode, Royal Crown Derby, Regal Doulton, Wedgwood and Worcester. In the United kingdom, references to "people's republic of china" or "porcelain" can refer to bone people's republic of china, and "English language porcelain" has been used as a term for it, both in the Great britain and effectually the world.[17] Fine china is not necessarily bone china, and is a term used to refer to ware which does not contain bone ash.[xi]

Surface treatments [edit]

Painting [edit]

China painting, or porcelain painting is the decoration of glazed porcelain objects such equally plates, bowls, vases or statues. The body of the object may be hard-paste porcelain, developed in Prc in the 7th or 8th century, or soft-paste porcelain (often bone china), adult in 18th-century Europe. The hypernym ceramic painting includes painted decoration on lead-glazed earthenware such as creamware or can-glazed pottery such as maiolica or faience. Typically the body is offset fired in a kiln to convert information technology into a hard porous biscuit. Underglaze ornament may and so be practical, followed past ceramic glaze, which is fired and then information technology bonds to the torso. The glazed porcelain may then exist decorated with overglaze painting and fired again at a lower temperature to bond the pigment with the glaze. Decoration may exist applied by castor or past stenciling, transfer press, lithography and screen printing.[18]

Slipware [edit]

Slipware is a type of pottery identified by its primary decorating procedure where slip is placed onto the leather-hard dirt body surface before firing by dipping, painting or splashing. Sideslip is an aqueous interruption of a clay trunk, which is a mixture of clays and other minerals such as quartz, feldspar and mica. A coating of white or coloured sideslip, known as an engobe, tin can be applied to the commodity to improve its advent, to give a smoother surface to a rough body, mask an inferior colour or for decorative effect. Slips or engobes tin can also exist applied by painting techniques, in isolation or in several layers and colours. Sgraffito involves scratching through a layer of coloured skid to reveal a unlike color or the base body underneath. Several layers of slip and/or sgraffito tin can be done while the pot is nevertheless in an unfired state. I color of sideslip tin be fired, earlier a 2nd is applied, and prior to the scratching or incising decoration. This is particularly useful if the base body is not of the desired colour or texture.[nineteen]

Terra sigillata [edit]

In sharp contrast to the archaeological usage, in which the term terra sigillata refers to a whole grade of pottery, in contemporary ceramic art, 'terra sigillata' describes only a watery refined slip used to facilitate the burnishing of raw clay surfaces and used to promote carbon smoke furnishings, in both primitive low temperature firing techniques and unglazed alternative western-fashion Raku firing techniques. Terra sigillata is besides used as a brushable decorative colourant medium in higher temperature glazed ceramic techniques.[20]

Forms [edit]

Studio pottery [edit]

Studio pottery is pottery made by amateur or professional artists or artisans working alone or in small groups, making unique items or short runs. Typically, all stages of manufacture are carried out by the artists themselves.[21] Studio pottery includes functional wares such as tableware, cookware and non-functional wares such every bit sculpture. Studio potters can be referred to as ceramic artists, ceramists, ceramicists or as an artist who uses dirt equally a medium. Much studio pottery is tableware or cookware but an increasing number of studio potters produce not-functional or sculptural items. Some studio potters now adopt to call themselves ceramic artists, ceramists or just artists. Studio pottery is represented by potters all over the globe.

Tile [edit]

Tile, Hopi Pueblo (Native American), belatedly 19th–early 20th century

A tile is a manufactured piece of hard-wearing material such equally ceramic, rock, metal, or even glass, generally used for covering roofs, floors, walls, showers, or other objects such as tabletops. Alternatively, tile tin sometimes refer to like units made from lightweight materials such as perlite, wood, and mineral wool, typically used for wall and ceiling applications. In another sense, a "tile" is a construction tile or similar object, such as rectangular counters used in playing games (see tile-based game). The word is derived from the French word tuile, which is, in plough, from the Latin give-and-take tegula, meaning a roof tile equanimous of fired clay.

Tiles are often used to grade wall murals and floor coverings, and tin range from simple square tiles to complex mosaics. Tiles are most often made of ceramic, typically glazed for internal uses and unglazed for roofing, but other materials are also commonly used, such as drinking glass, cork, concrete and other blended materials, and stone. Tiling rock is typically marble, onyx, granite or slate. Thinner tiles tin be used on walls than on floors, which require more durable surfaces that will resist impacts.

Figurines [edit]

A figurine (a diminutive grade of the word figure) is a statuette that represents a human being, deity, legendary creature, or animal. Figurines may be realistic or iconic, depending on the skill and intention of the creator. The earliest were made of stone or clay. In ancient Greece, many figurines were fabricated from terracotta (run across Greek terracotta figurines). Modern versions are made of ceramic, metallic, glass, wood and plastic. Figurines and miniatures are sometimes used in board games, such every bit chess, and tabletop role playing games. Old figurines accept been used to disbelieve some historical theories, such as the origins of chess.

Tableware [edit]

Tableware is the dishes or dishware used for setting a table, serving food and dining. It includes cutlery, glassware, serving dishes and other useful items for practical too as decorative purposes.[22] [23] Dishes, bowls and cups may be fabricated of ceramic, while cutlery is typically fabricated from metal, and glassware is frequently fabricated from glass or other not-ceramic materials. The quality, nature, variety and number of objects varies according to culture, religion, number of diners, cuisine and occasion. For example, Middle Eastern, Indian or Polynesian nutrient civilization and cuisine sometimes limits tableware to serving dishes, using bread or leaves every bit private plates. Special occasions are usually reflected in higher quality tableware.[23]

Terracotta (artworks) [edit]

In addition to being a material, "terra cotta" besides refers to items made out of this fabric. In archaeology and fine art history, "terracotta" is often used to draw objects such as statures, and figurines non made on a potter'due south wheel. A prime example is the Terra cotta Army, a collection of human being-sized terracotta sculptures depicting the armies of Qin Shi Huang, the get-go Emperor of China. It is a class of funerary art buried with the emperor in 210–209BCE and whose purpose was to protect the emperor in his afterlife.[24]

French sculptor Albert-Ernest Carrier-Belleuse made many terracotta pieces, but possibly the near famous is The Abduction of Hippodameia depicting the Greek mythological scene of a centaur kidnapping Hippodameia on her wedding ceremony day. American architect Louis Sullivan is well known for his elaborate glazed terracotta ornamentation, designs that would take been impossible to execute in whatsoever other medium. Terra cotta and tile were used extensively in the town buildings of Victorian Birmingham, England.

History [edit]

There is a long history of ceramic art in nigh all adult cultures, and ofttimes ceramic objects are all the artistic testify left from vanished cultures, like that of the Nok in Africa over 3,000 years ago.[25] Cultures especially noted for ceramics include the Chinese, Cretan, Greek, Farsi, Mayan, Japanese, and Korean cultures, as well as the modern Western cultures. There is evidence that pottery was independently invented in several regions of the earth, including East asia, Sub-Saharan Africa, the Near East, and the Americas.

Paleolithic pottery (c. twenty,000 BP) [edit]

20,000-ten,000 twelvemonth sometime pottery with re-construction repairs found in the Xianrendong cave, China.[26] [27] [28]

Although pottery figurines are found from earlier periods in Europe, the oldest pottery vessels come up from East Asia, with finds in China and Japan, and then still linked by a land bridge, and some in what is at present the Russian Far Due east, providing several from 20,000–10,000BCE, although the vessels were uncomplicated commonsensical objects.[29] [xxx] Xianrendong Cave in Jiangxi province contained pottery fragments that date back to 20,000 years ago.[31] [32] These early pottery containers were made well before the invention of agriculture, by mobile foragers who hunted and gathered their food during the Late Glacial Maximum.[27] Many of the pottery fragments had scorch marks, suggesting that the pottery was used for cooking.[27]

Before Neolithic pottery: rock containers (12,000–half dozen,000 BC) [edit]

Many remarkable containers were made from stone before the invention of pottery in Western Asia (which occurred effectually vii,000 BC), and before the invention of agriculture. The Natufian culture created elegant stone mortars during the period between 12,000 and ix,500 BC. Around 8000 BC, several early settlements became experts in crafting cute and highly sophisticated containers from stone, using materials such equally alabaster or granite, and employing sand to shape and polish. Artisans used the veins in the material to maximize visual issue. Such object accept been found in abundance on the upper Euphrates river, in what is today eastern Syria, especially at the site of Bouqras.[33] These form the early stages of the development of the Art of Mesopotamia.

-

Rock mortar from Eynan, Natufian period, 12,500-9,500 BC

-

Calcite tripod vase, mid-Euphrates, probably from Tell Buqras, half-dozen,000 BC, Louvre Museum AO 31551

-

Alabaster pot Mid-Euphrates region, six,500 BC, Louvre Museum

-

Alabaster pot, Mid-Euphrates region, 6,500 BC, Louvre Museum

Neolithic pottery (6,500–3,500 BC) [edit]

Early on pots were made past what is known as the "coiling" method, which worked the clay into a long string that wound to grade a shape that later fabricated smoothen walls. The potter'due south bicycle was probably invented in Mesopotamia by the fourth millennium BCE, simply spread across nearly all Eurasia and much of Africa, though it remained unknown in the New Earth until the arrival of Europeans. Decoration of the clay past incising and painting is found very widely, and was initially geometric, only often included figurative designs from very early on.

So important is pottery to the archaeology of prehistoric cultures that many are known past names taken from their distinctive, and oftentimes very fine, pottery, such as the Linear Pottery civilization, Chalice civilization, Globular Amphora culture, Corded Ware culture and Funnelbeaker civilization, to take examples only from Neolithic Europe (approximately 7000–1800BCE).

Ceramic fine art has generated many styles from its ain tradition, but is often closely related to contemporary sculpture and metalwork. Many times in its history styles from the usually more prestigious and expensive fine art of metalworking accept been copied in ceramics. This tin exist seen in early Chinese ceramics, such as pottery and ceramic-wares of the Shang Dynasty, in Ancient Roman and Iranian pottery, and Rococo European styles, copying contemporary silverware shapes. A common use of ceramics is for "pots" - containers such as bowls, vases and amphorae, as well equally other tableware, but figurines accept been very widely made.

Ceramics equally wall ornament [edit]

The earliest evidence of glazed brick is the discovery of glazed bricks in the Elamite Temple at Chogha Zanbil, dated to the 13th century BCE. Glazed and coloured bricks were used to make depression reliefs in Ancient Mesopotamia, most famously the Ishtar Gate of Babylon (c. 575BCE), at present partly reconstructed in Berlin, with sections elsewhere. Mesopotamian craftsmen were imported for the palaces of the Western farsi Empire such as Persepolis. The tradition continued, and after the Islamic conquest of Persia coloured and often painted glazed bricks or tiles became an of import element in Western farsi architecture, and from there spread to much of the Islamic world, notably the İznik pottery of Turkey under the Ottoman Empire in the 16th and 17th centuries.

Using the lusterware engineering science, one of the finest examples of medieval Islamic use of ceramics every bit wall decoration can be seen in the Mosque of Uqba as well known every bit the Bully Mosque of kairouan (in Tunisia), the upper office of the mihrab wall is adorned with polychrome and monochrome lusterware tiles; dating from 862 to 863, these tiles were most probably imported from Mesopotamia.[34] [35]

Transmitted via Islamic Spain, a new tradition of Azulejos developed in Espana and especially Portugal, which by the Bizarre menstruum produced extremely large painted scenes on tiles, unremarkably in blue and white. Delftware tiles, typically with a painted blueprint covering only one (rather minor) tile, were ubiquitous in the Netherlands and widely exported over Northern Europe from the 16th century on. Several 18th-century royal palaces had porcelain rooms with the walls entirely covered in porcelain. Surviving examples include ones at Capodimonte, Naples, the Royal Palace of Madrid and the nearby Royal Palace of Aranjuez.[36] Elaborate cocklestoves were a feature of rooms of the eye and upper-classes in Northern Europe from the 17th to 19th centuries.

There are several other types of traditional tiles that remain in industry, for example, the small, almost mosaic, brightly coloured zellige tiles of Morocco. With exceptions, notably the Porcelain Tower of Nanjing, tiles or glazed bricks do not feature largely in East Asian ceramics.

Regional developments [edit]

Although pottery figurines are constitute from earlier periods in Europe, the oldest pottery vessels come up from East Asia, with finds in China and Japan, so nonetheless linked by a state span, and some in what is now the Russian Far East, providing several from between 20,000 and 10,000 BCE, although the vessels were uncomplicated utilitarian objects.[29] [30] Xianrendong Cave in Jiangxi province contained pottery fragments that date back to 20,000 years agone.[31] [32]

Cambodia [edit]

Recent archaeological excavations at Angkor Borei (in southern Cambodia) accept recovered a large number of ceramics, some of which probably appointment dorsum to the prehistoric period. Most of the pottery, however, dates to the pre-Angkorian menstruum and consists mainly of pinkish terracotta pots which were either hand-made or thrown on a cycle, and and so decorated with incised patterns.

Glazed wares first appear in the archaeological record at the finish of the 9th century at the Roluos temple group in the Angkor region, where green-glazed pot shards take been establish. A chocolate-brown glaze became popular at the first of the 11th century and chocolate-brown-glazed wares accept been found in abundance at Khmer sites in northeast Thailand. Decorating pottery with animal forms was a popular style from the 11th to 13th century. Archaeological excavations in the Angkor region accept revealed that towards the terminate of Angkor period production of ethnic pottery declined while at that place was a dramatic increase in Chinese ceramic imports.

Direct prove of the shapes of vessels is provided by scenes depicted on bas-reliefs at Central khmer temples, which as well offering insight into domestic and ritualistic uses of the wares. The wide range of commonsensical shapes suggest the Khmers used ceramics in their daily life for cooking, food preservation, carrying and storing liquids, equally containers for medicinal herbs, perfumes and cosmetics.[37]

Communist china [edit]

Chinese Longquan celadon, Vocal Dynasty, 13th century. Celadon was first made in Mainland china, and and so exported to various parts of Asia and Europe. Celadon became a favourite of various kings and monarchs, such every bit the Ottoman Sultans, because of its pristine beauty, its resemblance to Chinese jade, and the belief that the celadon would change its colour if the food or vino were poisoned.[38]

At that place is Chinese porcelain from the late Eastern Han menses (100–200CE), the Three Kingdoms menstruum (220–280CE), the Six Dynasties flow (220–589CE), and thereafter. China in particular has had a continuous history of large-calibration production, with the Majestic factories normally producing the all-time work. The Tang Dynasty (618 to 906CE) is specially noted for grave appurtenances figures of humans, animals and model houses, boats and other goods, excavated (usually illegally) from graves in large numbers.

Some experts believe the start true porcelain was made in the province of Zhejiang in Cathay during the Eastern Han menstruation. Shards recovered from archaeological Eastern Han kiln sites estimated firing temperature ranged from 1,260 to 1,300 °C (ii,300 to 2,370 °F).[39] Every bit far back as 1000 BCE, the so-chosen "porcelaneous wares" or "proto-porcelain wares" were made using at least some kaolin fired at high temperatures. The dividing line between the 2 and true porcelain wares is not a clear one. Archaeological finds take pushed the dates to as early on every bit the Han Dynasty (206–BCE – 220CE).[40]

The Purple porcelain of the Song Dynasty (960–1279), featuring very subtle decoration shallowly carved by pocketknife in the clay, is regarded by many authorities equally the peak of Chinese ceramics, though the large and more exuberantly painted ceramics of the Ming Dynasty (1368–1644) have a wider reputation.

Chinese emperors gave ceramics as diplomatic gifts on a lavish scale, and the presence of Chinese ceramics no doubtfulness aided the evolution of related traditions of ceramics in Japan and Korea in detail.

Until the 16th century, modest quantities of expensive Chinese porcelain were imported into Europe. From the 16th century onwards attempts were made to imitate information technology in Europe, including soft-paste and the Medici porcelain made in Florence. None was successful until a recipe for hard-paste porcelain was devised at the Meissen mill in Dresden in 1710. Within a few years, porcelain factories sprung up at Nymphenburg in Bavaria (1754) and Capodimonte in Naples (1743) and many other places, frequently financed by a local ruler.

Japan [edit]

Nabeshima plate with iii herons

A celadon incense burner from the Goryeo Dynasty with Korean kingfisher glaze. National Treasure No.95 of South korea

The primeval Japanese pottery was made around the 11th millennium BCE. Jōmon ware emerged in the 6th millennium BCE and the plainer Yayoi style in well-nigh the 4th century BCE. This early pottery was soft earthenware, fired at low temperatures. The potter'south wheel and a kiln capable of reaching college temperatures and firing stoneware appeared in the 3rd or fourth centuries CE, probably brought from Cathay via the Korean peninsula.[41] In the 8th century, official kilns in Japan produced simple, green atomic number 82-glazed earthenware. Unglazed stoneware was used as funerary jars, storage jars and kitchen pots up to the 17th century. Some of the kilns improved their methodsmil[ clarification needed ] From the 11th to the 16th century, Nippon imported much porcelain from Communist china and some from Korea. The Japanese overlord Toyotomi Hideyoshi's attempts to conquer China in the 1590s were dubbed the "Ceramic Wars";[ citation needed ] the emigration of Korean potters appeared to be a major cause. One of these potters, Yi Sam-pyeong, discovered the raw material of porcelain in Arita and produced beginning true porcelain in Japan.

In the 17th century, conditions in China drove some of its potters into Nippon, bringing with them the knowledge to make refined porcelain. From the mid-century, the Dutch East Bharat Company began to import Japanese porcelain into Europe. At this time, Kakiemon wares were produced at the factories of Arita, which had much in common with the Chinese Famille Verte style. The superb quality of its enamel ornament was highly prized in the Westward and widely imitated by the major European porcelain manufacturers. In 1971 it was declared an important "intangible cultural treasure" by the Japanese government.

In the 20th century, involvement in the art of the village potter was revived by the Mingei folk movement led by potters Shoji Hamada, Kawai Kajiro and others. They studied traditional methods in order to preserve native wares that were in danger of disappearing. Modern masters apply ancient methods to bring pottery and porcelain to new heights of accomplishment at Shiga, Iga, Karatsu, Hagi, and Bizen. A few outstanding potters were designated living cultural treasures (mukei bunkazai 無形文化財). In the quondam capital of Kyoto, the Raku family unit continued to produce the rough tea bowls that had so delighted connoisseurs. At Mino, potters continued to reconstruct the classic formulas of Momoyama-era Seto-type tea wares of Mino, such equally Oribe ware. By the 1990s many primary potters worked away from ancient kilns and fabricated classic wares in all parts of Japan.

Korea [edit]

Korean pottery has had a continuous tradition since uncomplicated earthenware from about 8000 BCE. Styles have mostly been a distinctive variant of Chinese, and later on Japanese, developments. The ceramics of the Goryeo Dynasty (918–1392) and early Joseon white porcelain of the post-obit dynasty are generally regarded as the finest achievements.[42]

Western Asia and the Eye E [edit]

Islamic pottery [edit]

From the eighth to 18th centuries, glazed ceramics was of import in Islamic art, usually in the course of elaborate pottery,[43] developing on vigorous Persian and Egyptian pre-Islamic traditions in item. Tin-opacified glazing was developed past the Islamic potters, the first examples plant every bit bluish-painted ware in Basra, dating from most the 8th century. The Islamic world had contact with Cathay, and increasingly adapted many Chinese decorative motifs. Western farsi wares gradually relaxed Islamic restrictions on figurative ornament, and painted figuratives scenes became very important.

Ceramic bowl decorated with slip beneath a transparent coat, Gorgan, 9th century CE, Early Islamic menstruum, National Museum of Islamic republic of iran

Stoneware was also an important craft in Islamic pottery, produced throughout Iraq and Syria by the 9th century.[44] Pottery was produced in Raqqa, Syrian arab republic, in the 8th century.[45] Other centers for innovative ceramics in the Islamic earth were Fustat (virtually modern Cairo) from 975 to 1075, Damascus from 1100 to around 1600 and Tabriz from 1470 to 1550.[46]

The albarello form, a type of maiolica earthenware jar originally designed to hold apothecaries' ointments and dry drugs, was first fabricated in the Islamic Eye E. Information technology was brought to Italy by Hispano-Moresque traders; the earliest Italian examples were produced in Florence in the 15th century.

Iznik pottery, fabricated in western Anatolia, is highly busy ceramics whose heyday was the late 16th century under the Ottoman sultans. Iznik vessels were originally made in imitation of Chinese porcelain, which was highly prized. Under Süleyman the Magnificent (1520–66), need for Iznik wares increased. Subsequently the conquest of Constantinople in 1453, the Ottoman sultans started a programme of building, which used large quantities of Iznik tiles. The Sultan Ahmed Mosque in Istanbul (built 1609–16) alone contains 20,000 tiles and tiles were used extensively in the Topkapi Palace (commenced 1459). As a result of this demand, tiles dominated the output of the Iznik potteries.

Europe [edit]

Early figurines [edit]

The primeval known ceramic objects are the Gravettian figurines from the Upper Paleolithic flow, such every bit those discovered at Dolní Věstonice in the modernistic-day Czechia. The Venus of Dolní Věstonice (Věstonická Venuše in Czech) is a statuette of a nude female figure dating from some fourth dimension from 29,000–25,000 BCE.[47] Information technology was fabricated by moulding and so firing a mixture of clay and powdered bone.[48] Similar objects in various media found throughout Europe and Asia and dating from the Upper Paleolithic menstruation have also been called Venus figurines. Scholars are not agreed as to their purpose or cultural significance.

The ancient Mediterranean [edit]

Glazed Egyptian faience dates to the third millennium BCE), with painted merely unglazed pottery used even earlier during the predynastic Naqada culture. Faience became sophisticated and produced on a large scale, using moulds likewise modelling, and afterward besides throwing on the bicycle. Several methods of glazing were developed, but colours remained largely limited to a range in the blue-green spectrum.

On the Greek island of Santorini are some of the earliest finds created by the Minoans dating to the third millennium BCE, with the original settlement at Akrotiri dating to the fourth millennium BCE;[49] excavation work continues at the master archaeological site of Akrotiri. Some of the excavated homes contain huge ceramic storage jars known as pithoi.

Aboriginal Greek and Etruscan ceramics are renowned for their figurative painting, especially in the blackness-effigy and carmine-figure styles. Moulded Greek terra cotta figurines, especially those from Tanagra, were small-scale figures, often religious but subsequently including many of everyday genre figures, obviously used purely for decoration.

Ancient Roman pottery, such as Samian ware, was rarely every bit fine, and largely copied shapes from metalwork, simply was produced in enormous quantities, and is institute all over Europe and the Eye East, and beyond. Monte Testaccio is a waste mound in Rome made nigh entirely of cleaved amphorae used for transporting and storing liquids and other products. Few vessels of keen creative involvement have survived, but there are very many minor figures, often incorporated into oil lamps or similar objects, and frequently with religious or erotic themes (or both together – a Roman speciality). The Romans more often than not did not leave grave goods, the best source of ancient pottery, but even and then they practise not seem to have had much in the style of luxury pottery, unlike Roman glass, which the elite used with gold or silver tableware. The more expensive pottery tended to utilise relief decoration, often moulded, rather than paint. Especially in the Eastern Empire, local traditions continued, hybridizing with Roman styles to varying extents.

Tin-glazed pottery [edit]

A Hispano-Moresque dish, approx 32 cm (13 in) diameter, with Christian monogram "IHS", busy in cobalt bluish and gilded lustre. Valencia, c. 1430–1500. Burrell Collection

Tin-glazed pottery, or faience, originated in Iraq in the 9th century, from where information technology spread to Egypt, Persia and Spain before reaching Italy in the Renaissance, Holland in the 16th century and England, France and other European countries shortly after. Important regional styles in Europe include: Hispano-Moresque, maiolica, Delftware, and English Delftware. By the High Centre Ages the Hispano-Moresque ware of Al-Andaluz was the nearly sophisticated pottery being produced in Europe, with elaborate decoration. It introduced can-glazing to Europe, which was developed in the Italian Renaissance in maiolica. Tin-glazed pottery was taken up in holland from the 16th to the 18th centuries, the potters making household, decorative pieces and tiles in vast numbers,[l] unremarkably with blueish painting on a white basis. Dutch potters took tin-glazed pottery to the British Isles, where information technology was made between about 1550 and 1800. In France, tin can-coat was begun in 1690 at Quimper in Brittany,[51] followed in Rouen, Strasbourg and Lunéville. The development of white, or nearly white, firing bodies in Europe from the tardily 18th century, such every bit Creamware by Josiah Wedgwood and porcelain, reduced the demand for Delftware, faience and majolica. Today, can oxide usage in glazes finds limited use in conjunction with other, lower cost opacifying agents, although it is mostly restricted to specialist low temperature applications and utilize past studio potters,[52] [53] including Picasso who produced pottery using tin glazes.

Porcelain [edit]

Until the 16th century, pocket-size quantities of expensive Chinese porcelain were imported into Europe. From the 16th century onwards attempts were fabricated to imitate information technology in Europe, including soft-paste and the Medici porcelain made in Florence. In 1712, many of the elaborate Chinese porcelain manufacturing secrets were revealed throughout Europe by the French Jesuit father Francois Xavier d'Entrecolles and soon published in the Lettres édifiantes et curieuses de Chine par des missionnaires jésuites [54] Later on much experimentation, a recipe for hard-paste porcelain was devised at the Meissen porcelain factory in Dresden soon later 1710, and was on sale by 1713. Within a few decades, porcelain factories sprung up at Nymphenburg in Bavaria (1754) and Capodimonte in Naples (1743) and many other places, often financed by a local ruler.

Soft-paste porcelain was fabricated at Rouen in the 1680s, but the starting time important production was at St.Deject, messages-patent being granted in 1702. The Duc de Bourbon established a soft-paste manufacturing plant, the Chantilly porcelain, in the grounds of his Château de Chantilly in 1730; a soft-paste mill was opened at Mennecy; and the Vincennes factory was ready by workers from Chantilly in 1740, moving to larger premises at Sèvres[55] [56] in 1756. The superior soft-paste made at Sèvres put it in the leading position in Europe in the 2d half of the 18th century.[57] The first soft-paste in England was demonstrated in 1742, apparently based on the Saint-Cloud formula. In 1749 a patent was taken out on the kickoff bone cathay, subsequently perfected by Josiah Spode. The master English porcelain makers in the 18th century were at Chelsea, Bow, St James'southward, Bristol, Derby and Lowestoft.

Porcelain was ideally suited to the energetic Rococo curves of the day. The products of these early decades of European porcelain are generally the most highly regarded, and expensive. The Meissen modeler Johann Joachim Kaendler and Franz Anton Bustelli of Nymphenburg are possibly the well-nigh outstanding ceramic artists of the catamenia. Like other leading modelers, they trained as sculptors and produced models from which moulds were taken.

By the end of the 18th century owning porcelain tableware and decorative objects had become obligatory amid the prosperous middle-classes of Europe, and there were factories in most countries, many of which are still producing. As well as tableware, early European porcelain revived the taste for purely decorative figures of people or animals, which had too been a feature of several aboriginal cultures, often as grave goods. These were even so being produced in Communist china equally blanc de Chine religious figures, many of which had reached Europe. European figures were almost entirely secular, and soon brightly and brilliantly painted, often in groups with a modelled setting, and a strong narrative chemical element (see picture).

Wedgwood and the Northward Staffordshire Potteries [edit]

From the 17th century, Stoke-on-Trent in North Staffordshire emerged as a major middle of pottery making.[58] Important contributions to the development of the industry were made by the firms of Wedgwood, Spode, Royal Doulton and Minton.

The local presence of abundant supplies of coal and suitable clay for earthenware production led to the early only at first limited development of the local pottery industry. The construction of the Trent and Mersey Canal allowed the piece of cake transportation of prc clay from Cornwall together with other materials and facilitated the product of creamware and os china. Other production centres had a lead in the production of high quality wares simply the preeminence of Due north Staffordshire was brought about by methodical and detailed enquiry and a willingness to experiment carried out over many years, initially by one human being, Josiah Wedgwood. His atomic number 82 was followed by other local potters, scientists and engineers.

Wedgwood is credited with the industrialization of the manufacture of pottery. His work was of very high quality: when visiting his workshop, if he saw an offending vessel that failed to encounter with his standards, he would smash it with his stick, exclaiming, "This will non do for Josiah Wedgwood!" He was keenly interested in the scientific advances of his twenty-four hour period and it was this interest that underpinned his adoption of its arroyo and methods to revolutionize the quality of his pottery. His unique glazes began to distinguish his wares from anything else on the market. His matt finish jasperware in two colours was highly suitable for the Neoclassicism of the terminate of the century, imitating the furnishings of Ancient Roman carved gemstone cameos like the Gemma Augustea, or the cameo glass Portland Vase, of which Wedgwood produced copies.

He as well is credited with perfecting transfer-printing, offset developed in England well-nigh 1750. By the end of the century this had largely replaced hand-painting for circuitous designs, except at the luxury stop of the market, and the vast bulk of the globe's decorated pottery uses versions of the technique to the nowadays day. The perfecting of underglaze transfer printing is widely credited to Josiah Spode the first. The procedure had been used as a evolution from the processes used in volume printing, and early paper quality made a very refined detail in the blueprint incapable of reproduction, so early on print patterns were rather lacking in subtlety of tonal variation. The evolution of machine made thinner press papers around 1804 allowed the engravers to apply a much wider variety of tonal techniques which became capable of existence reproduced on the ware, much more successfully.

Far from perfecting underglaze print Wedgwood was persuaded by his painters non to prefer underglaze press until information technology became evident that Mr Spode was taking away his business through competitive pricing for a much more heavily decorated high quality product.

Stoke-on-Trent'southward supremacy in pottery manufacture nurtured and attracted a big number of ceramic artists including Clarice Cliff, Susie Cooper, Lorna Bailey, Charlotte Rhead, Frederick Hurten Rhead and Jabez Vodrey.

Studio pottery in Britain [edit]

Studio pottery is made past artists working lone or in small groups, producing unique items or short runs, typically with all stages of manufacture carried out by one private.[21] Information technology is represented by potters all over the globe but has strong roots in Britain, with potters such as Bernard Leach, William Staite Murray, Dora Billington, Lucie Rie and Hans Coper. Bernard Leach (1887–1979) established a manner of pottery influenced by Far-Eastern and medieval English forms. After briefly experimenting with earthenware, he turned to stoneware fired to loftier temperatures in large oil- or wood-burning kilns. This style dominated British studio pottery in the mid-20th-century. The Austrian refugee Lucie Rie (1902–1995) has been regarded equally essentially a modernist who experimented with new glaze effects on oftentimes brightly coloured bowls and bottles. Hans Coper (1920–1981) produced not-functional, sculptural and unglazed pieces. Later on the 2d Globe State of war, studio pottery in United kingdom was encouraged by the wartime ban on decorating manufactured pottery and the modernist spirit of the Festival of Uk. The simple, functional designs chimed in with the modernist ethos. Several potteries were formed in response to this fifties boom, and this style of studio pottery remained popular into the nineteen-seventies.[59] Elizabeth Fritsch (1940-) took up ceramics working nether Hans Coper at the Royal Higher of Art (1968–1971). Fritsch was i of a group of outstanding ceramicists who emerged from the Royal Higher of Art at that fourth dimension. Fritschs' ceramic vessels broke abroad from traditional methods and she developed a hand built flattened curlicue technique in stoneware smoothed and refined into accurately profiled forms. They are then hand painted with dry matt slips, in colours unusual for ceramics.

Pottery in Frg [edit]

German pottery has its roots in the alchemistry laboratories searching for gold product.

- Royal Porcelain Manufactory, Berlin

- Meissen porcelain

- Nymphenburg porcelain[60]

- Hutschenreuther

Pottery in Republic of austria [edit]

In 1718 a pottery was founded in Vienna.[61]

Pottery in Russia [edit]

The Imperial Porcelain Manufacture was founded in 1744 in Oranienbaum, Russia.[62] Information technology was based on the invention of porcelain by D. I. Winogradow (independent from Böttgers invention 1708, Dresden). An important collection of antique porcelain is preserved in the Russian Museum of Ceramics.

The Americas [edit]

Anasazi mugs from the Four Corners area, Southwestern US. Note the T-shaped cut-out in the left mug'southward handle. Ancestral Puebloan doorways ofttimes have this same shape.

Native American pottery [edit]

The people in North, Central, and Southward America continents had a broad variety of pottery traditions before Europeans arrived. The oldest ceramics known in the Americas—made from v,000 to 6,000 years ago—are found in the Andean region, along the Pacific declension of Republic of ecuador at Valdivia and Puerto Hormiga, and in the San Jacinto Valley of Republic of colombia; objects from iii,800 to iv,000 years old have been discovered in Peru. Some archaeologists believe that ceramics know-how institute its manner by sea to Mesoamerica, the second great cradle of civilization in the Americas.[63]

The best-adult styles found in the central and southern Andes are the ceramics establish well-nigh the formalism site at Chavín de Huántar (800–400BCE) and Cupisnique (1000–400BCE). During the same flow, another culture adult on the southern coast of Peru, in the expanse chosen Paracas. The Paracas civilization (600–100BCE) produced marvelous works of embossed ceramic finished with a thick oil applied after firing. This colorful tradition in ceramics and textiles was followed by the Nazca culture (1–600CE), whose potters developed improved techniques for preparing clay and for decorating objects, using fine brushes to paint sophisticated motifs. In the early stage of Nazca ceramics, potters painted realistic characters and landscapes.

The Moche cultures (one–800CE) that flourished on the northern coast of modern Republic of peru produced modelled clay sculptures and effigies decorated with fine lines of red on a biscuit background. Their pottery stands out for its huacos portrait vases, in which human faces are shown expressing different emotions—happiness, sadness, anger, melancholy—as well for its complicated drawings of wars, human sacrifices, and celebrations.[64]

The Maya were relative latecomers to ceramic development, as their ceramic arts flourished in the Maya Archetype Period, or the 2nd to 10th century. One important site in southern Belize is known as Lubaantun, that boasts particularly detailed and prolific works. Equally evidence of the extent to which these ceramic fine art works were prized, many specimens traced to Lubaantun have been found at distant Maya sites in Honduras and Guatemala.[65] Furthermore, the current Maya people of Lubaantun continue to hand produce copies of many of the original designs found at Lubaantun.

In the United States, the oldest pottery dates to 2500BCE. Information technology has been found in the Timucuan Ecological and Celebrated Preserve in Jacksonville, Florida, and some slightly older along the Savannah River in Georgia.[66]

The Hopi in Northern Arizona and several other Puebloan peoples including the Taos, Acoma, and Zuñi people (all in the Southwestern United States) are renowned for painted pottery in several different styles. Nampeyo[67] and her relatives created pottery that became highly sought after get-go in the early 20th century. Pueblo tribes in the state of New Mexico take styles distinctive to each of the various pueblos (villages). They include Santa Clara Pueblo, Taos Pueblo, Hopi Pueblos, San Ildefonso Pueblo, Acoma Pueblo and Zuni Pueblo, amongst others. Some of the renowned artists of Pueblo pottery include: Nampeyo, Elva Nampeyo, and Dextra Quotskuyva of the Hopi; Leonidas Tapia of San Juan Pueblo; and Maria Martinez and Julian Martinez of San Ildefonso Pueblo. In the early 20th century Martinez and her husband Julian rediscovered the method of creating traditional San Ildefonso Pueblo Blackness-on Black pottery.

Mexican ceramics [edit]

Mexican ceramics are an ancient tradition. Precolumbian potters built up their wares with pinching, coiling, or hammer-an-anvil methods and, instead of using glaze, burnished their pots.

Studio pottery in the Us [edit]

There is a strong tradition of studio artists working in ceramics in the United States. It had a period of growth in the 1960s and continues to nowadays times. Many fine art, arts and crafts, and contemporary art museums have pieces in their permanent collections. Beatrice Woods was an American artist and studio potter located in Ojai, California. She developed a unique grade of luster-glaze technique, and was active from the 1930s to her death in 1998 at 105 years old. Robert Arneson created larger sculptural work, in an abstracted representational style. There are ceramics arts departments at many colleges, universities, and fine arts institutes in the United States.

Sub-Saharan Africa [edit]

It appears that pottery was independently adult in Sub-Saharan Africa during the tenth millennium BC, with findings dating to at least ix,400 BC from primal Republic of mali.[68] In Africa, the primeval pottery has been found in the big mountain massifs of the Central Sahara, in the Eastern Sahara, and the Nile Valley, dating back to betwixt the ninth and tenth millennium. [69]

Pottery in Sub-Saharan Africa is traditionally made by coiling and is fired at low temperature. The figurines of the ancient Nok civilization, whose part remains unclear, are an example of high-quality figural work, found in many cultures, such as the Benin of Nigeria.

In the Aïr Region of Niger (W Africa) (Haour 2003) pottery dating from around x,000 BCE was excavated.[70]

Ladi Kwali, a Nigerian potter who worked in the Gwari tradition, made big pots decorated with incised patterns. Her work is an interesting hybrid of traditional African with western studio pottery. Magdalene Odundo is a Kenyan-born British studio potter whose ceramics are mitt built and burnished.

Ceramics museums and museum collections [edit]

A ceramics museum is a museum wholly or largely devoted to ceramics, normally ceramic artworks, whose collections may include drinking glass and enamel as well, simply volition normally concentrate on pottery, including porcelain. Most national ceramics collections are in a more full general museum covering all the arts, or but the decorative arts, simply in that location are a number of specialized ceramics museums, some concentrating on the production of just one country, region or manufacturer. Others take international collections, which may concentrate on ceramics from Europe or Eastern asia, or have global coverage.

In Asian and Islamic countries ceramics are normally a strong feature of general and national museums.[ citation needed ] Also most specialist archaeological museums, in all countries, take large ceramics collections, as pottery is the commonest type of archaeological antiquity.[71] Virtually of these are broken shards however.

Outstanding major ceramics collections in general museums include The Palace Museum, Beijing, with 340,000 pieces,[72] and the National Palace Museum in Taipei metropolis, Taiwan (25,000 pieces);[73] both are more often than not derived from the Chinese Majestic collection, and are most entirely of pieces from China. In London, the Victoria and Albert Museum (over 75,000 pieces, mostly after 1400 CE) and British Museum (mostly before 1400 CE) have very stiff international collections. The Metropolitan Museum of Art in New York and Freer Gallery of Art in Washington DC (thousands, all Asian[74]) have perhaps the best of the many fine collections in the large city museums of the U.s.. The Corning Museum of Glass, in Corning, New York, has more than than 45,000 glass objects.

-

100 BCE – 250 CE

-

-

A funerary urn in the shape of a "bat god" or a jaguar, from Oaxaca, Mexico, dated to 300–650 CE. Elevation: 9.5 in (23 cm).

-

Meet as well [edit]

- American Museum of Ceramic Fine art

- Listing of studio potters

- Sculpture – Artworks that are three-dimensional objects

- Visual arts – Art forms that create works that are primarily visual in nature

References [edit]

Citations [edit]

- ^ "Art Pottery Manufacturers and Collectors". Archived from the original on ii June 2008. Retrieved 5 Jan 2003.

- ^ The Webster Encyclopedic Dictionary

- ^ "Earthenware" Britannica online

- ^ OED, "Terracotta"

- ^ 'Diagnosis Of Terra-Cotta Coat Spalling.' Due south.E. Thomasen, C.L. Searls. Masonry: Materials, Design, Construction and Maintenance. ASTM STP 992 Philadelphia, USA, 1988. American Society for Testing & Materials.

- ^ 'Colour Degradation In A Terra Cotta Glaze' H.J. Lee, Due west.K. Carty, J.Gill. Ceram.Eng.Sci.Proc. 21, No.2, 2000, p. 45–58.

- ^ 'High-lead glaze compositions and alterations: instance of byzantine tiles.' A. Bouquillon. C. Pouthas. Euro Ceramics 5. Pt.2. Trans Tech Publications, Switzerland,1997, p. 1487–1490 Quote: "A collection of architectural Byzantine tiles in glazed terra cotta is stored and exhibited in the Fine art Object department of the Louvre Museum as well as in the Musee de la Ceramique de Sevres."

- ^ 'Industrial Ceramics.' F.Singer, S.S.Vocalizer. Chapman & Hall. 1971. Quote: "The lighter pieces that are glazed may also exist termed 'terracotta.'

- ^ Standard Terminology of Ceramic Whiteware and Related Products: ASTM Standard C242.

- ^ "What Temperature Should I Fire My Clay To?". bigceramicstore.com . Retrieved 19 March 2016.

- ^ a b c d Dodd 1994.

- ^ Encyclopædia Britannica Jasperware is unglazed stoneware

- ^ Definition in The Combined Nomenclature of the European Communities defines, Burton, 1906

- ^ a b Ozgundogdu, Feyza Cakir. "Bone China from Turkey" Ceramics Technical; May2005, Issue twenty, p 29–32.

- ^ a b 'Trading Places.' R.Ware. Asian Ceramics. Nov,2009, p.35,37-39.

- ^ What is Mainland china? Equally with stoneware, the trunk becomes vitrified; which means the body fuses, becomes nonabsorbent, and very strong. Unlike stoneware, china becomes very white and translucent. Archived 14 June 2015 at the Wayback Machine

- ^ Osborne, Harold (ed), The Oxford Companion to the Decorative Arts, p. 130, 1975, OUP, ISBN 0-19-866113-four; Faulkner, Charles H., "The Ramseys at Swan Pond: The Archaeology and History of an East Tennessee Farm, p.96, 2008, Univ. of Tennessee Press, 2008, ISBN 1-57233-609-9, 9781572336094; Lawrence, Susan, "Archaeologies of the British: Explorations of Identity in the Britain and Its Colonies 1600–1945", p. 196, 2013, Routledge, ISBN ane-136-80192-8, 781136801921

- ^ Lewis, Florence (1883). China painting. Cassell.

- ^ Eden, Victoria and Michael. (1999) Slipware, Gimmicky Approaches. A & C Black, University of Pennsylvania Printing, G & B Arts International. ISBN 90-5703-212-0

- ^ Garbsch, Jochen, Terra Sigillata. (1982) Ein Weltreich im Spiegel seines Luxusgeschirrs, Munich. (in German)

- ^ a b Cooper 2010.

- ^ Bloomfield, Linda (2013). Contemporary tableware. London: A. & C. Black. ISBN978-1-4081-5395-6.

- ^ a b Venable, Charles L.; et al. (2000). China and Drinking glass in America, 1880–1980: From Table Peak to TV Tray. New York: Harry Due north. Abrams. ISBN978-0-8109-6692-5.

- ^ Portal, Jane (2007). The First Emperor: Cathay's Terracotta Army. Harvard University Press. ISBN978-0-674-02697-1.

- ^ Breunig, Peter. 2014. Nok: African Sculpture in Archaeological Context: p. 21.

- ^ Huan, Anthony (xiii April 2019). "Ancient China: Neolithic". National Museum of Mainland china.

- ^ a b c Bar-Yosef, Ofer; Arpin, Trina; Pan, Yan; Cohen, David; Goldberg, Paul; Zhang, Chi; Wu, Xiaohong (29 June 2012). "Early Pottery at 20,000 Years Ago in Xianrendong Cave, China". Scientific discipline. 336 (6089): 1696–1700. Bibcode:2012Sci...336.1696W. doi:10.1126/scientific discipline.1218643. ISSN 0036-8075. PMID 22745428. S2CID 37666548.

- ^ Marshall, Michael. "Oldest pottery hints at cooking's ice-age origins". www.newscientist.com.

- ^ a b "BBC NEWS – Science & Surround – 'Oldest pottery' found in China". bbc.co.britain. June 2009. Retrieved 19 March 2016.

- ^ a b Boaretto, Eastward.; et al. (2009). "Radiocarbon dating of charcoal and bone collagen associated with early pottery at Yuchanyan Cave, Hunan Province, China". Proceedings of the National University of Sciences. 106 (24): 9537–9538. Bibcode:2009PNAS..106.9595B. doi:10.1073/pnas.0900539106. PMC2689310. PMID 19487667.

- ^ a b "Harvard, BU researchers discover evidence of 20,000-yr-old pottery". Boston.com. Archived from the original on 2 January 2013. Retrieved two Jan 2013.

- ^ a b Stanglin, Douglas (29 June 2012). "Pottery found in Red china cave confirmed as world'due south oldest". USA Today.

- ^ "Metropolitan Museum of Art". www.metmuseum.org.

- ^ Catherine Hess, Linda Komaroff and George Saliba (2004), The arts of burn down: Islamic influences on glass and ceramics of the Italian Renaissance, Getty Publications, p. xl

- ^ "Qantara – Mihrāb of the Smashing Mosque of Kairouan". qantara-med.org. Archived from the original on 3 March 2016. Retrieved 19 March 2016.

- ^ Porcelain Room, Aranjuez Comprehensive but shaky video [ expressionless link ]

- ^ "Contact Support". cambodiamuseum.info . Retrieved 19 March 2016.

- ^ Britannica Online Archived 22 December 2007 at the Wayback Machine

- ^ He Li, (1996). Chinese Ceramics. The New Standard Guide. Thames and Hudson, London. ISBN 0-500-23727-1.

- ^ Temple, Robert M.G. (2007). The Genius of China: 3,000 Years of Scientific discipline, Discovery, and Invention (3rd edition). London: André Deutsch, pp. 103–vi. ISBN 978-0-233-00202-6

- ^ The Metropolitan Museum of Art [1] "Although the roots of Sueki reach back to ancient Mainland china, its direct forerunner is the grayware of the Iii Kingdoms menstruation in Korea."

- ^ "Drove: Korean Fine art". Freer/Sackler. Smithsonian Establishment. Archived from the original on 1 September 2015. Retrieved ii Baronial 2015.

- ^ Mason, Robert B. (1995). New Looks at Sometime Pots: Results of Recent Multidisciplinary Studies of Glazed Ceramics from the Islamic World. Muqarnas: Annual on Islamic Fine art and Architecture. Vol. XII. Brill Academic Publishers. ISBN978-ninety-04-10314-6. Mason (1995), p. one

- ^ Stonemason (1995), p. 5

- ^ Henderson, J.; McLoughlin, S. D.; McPhail, D. S. (2004). "Radical changes in Islamic drinking glass technology: evidence for conservatism and experimentation with new glass recipes from early and middle Islamic Raqqa, Syrian arab republic". Archaeometry. 46 (3): 439–68. doi:10.1111/j.1475-4754.2004.00167.x.

- ^ Mason (1995), p. 7

- ^ "No. 359: The Dolni Vestonice Ceramics". uh.edu . Retrieved 19 March 2016.

- ^ Chris Stringer. Homo Britannicus, Alan Lane, 2006, ISBN 978-0-7139-9795-eight.

- ^ "Archaeological site of akrotiri Santorini Greece". travel-to-santorini.com . Retrieved 19 March 2016.

- ^ Caiger-Smith, Alan, Can Glazed Pottery, Faber and Faber, 1973

- ^ Faience-de-quimper.com Archived 13 April 2005 at the Wayback Machine

- ^ 'Ceramic Glazes.' F.Singer & Due west.L.German. Borax Consolidated Express. London. 1960.

- ^ 'Ceramics Glaze Technology.' J.R. Taylor & A.C. Bull. The Institute Of Ceramics & Pergamon Press. Oxford. 1986.

- ^ Baghdiantz McAbe, Ina (2008). Orientalism in Early Modern France. Oxford: Berg Publishing, p. 220. ISBN 978-i-84520-374-0; Finley, Robert (2010). The pilgrim art. Cultures of porcelain in globe history. University of California Press, p. eighteen. ISBN 978-0-520-24468-ix; Kerr, R. & Forest, N. (2004). Joseph Needham : Scientific discipline and Civilisation in Mainland china, Volume 5 Chemical science and Chemical Applied science : Part 12 Ceramic Technology. Cambridge Academy Press, p. 36-7. ISBN 0-521-83833-9

- ^ "The 18th Century: The Ascension and Success". Manufacture nationale de Sèvres. Archived from the original on 24 November 2006.

- ^ "Sèvres Porcelain in the Nineteenth Century". The Met's Heilbrunn Timeline of Art History . Retrieved nineteen March 2016.

- ^ "French Porcelain in the Eighteenth Century". The Met'due south Heilbrunn Timeline of Art History . Retrieved 19 March 2016.

- ^ "all nigh Stoke-on-Trent in 5 minutes..." thepotteries.org . Retrieved 19 March 2016.

- ^ Harrod, Tanya, "From A Potter's Book to The Maker's Eye: British Studio Ceramics 1940–1982", in The Harrow Connection, Northern Centre for Contemporary Art, 1989

- ^ "HISTORY Porzellan Manufaktur Nymphenburg". Retrieved 24 July 2016.

- ^ "Porcelain Museum in the Augarten". Retrieved 25 July 2016.

- ^ "Majestic Porcelain: The History of Russian Imperial Porcelain from 1744 to 1917*". Retrieved 25 July 2016.

- ^ The New York Times, Art Review Museum of American Indian's 'Born of Clay' Explores Culture Through Ceramics Past GRACE GLUECK, Published: 1 July 2006

- ^ Built-in of Clay – Ceramic from the National Museum of the American Indian, 2005 Smithsonian Institution

- ^ C.M. Hogan, Comparison of Mayan sites in southern and western Belize, Lumina Technologies (2006)

- ^ Soergel, Matt (18 Oct 2009). "The Mocama: New name for an old people". The Florida Times-Wedlock . Retrieved 12 May 2010.

- ^ A Nampeyo Showcase Archived 24 September 2015 at the Wayback Car, a brandish of some of Nampeyo's work

- ^ Simon Bradley, A Swiss-led squad of archaeologists has discovered pieces of the oldest African pottery in fundamental Mali, dating back to at least 9,400BC Archived 2012-03-06 at the Wayback Motorcar, SWI swissinfo.ch – the international service of the Swiss Broadcasting Corporation (SBC), 18 January 2007

- ^ Jesse, Friederike (25 Oct 2010). "Early Pottery in Northern Africa – An Overview". Periodical of African Archeology. 8 (2): 219–238. doi:x.3213/1612-1651-10171. ISSN 1612-1651.

- ^ Olivier P. Gosselain (2008). "Ceramics in Africa". Encyclopaedia of the History of Scientific discipline, Technology, and Medicine in Non-Western Cultures. pp. 464–476. doi:10.1007/978-1-4020-4425-0_8911. ISBN978-1-4020-4559-2.

- ^ "Archaeological Analysis", Ohio State Archeological excavations in Greece

- ^ "Palace Museum Opens Its New Porcelain Hall". chinaculture.org. Archived from the original on three March 2016. Retrieved 19 March 2016.

- ^ "國立故宮全球資訊網-訊息頁". npm.gov.tw . Retrieved 19 March 2016.

- ^ Peterson 1996, p. 369.

Sources [edit]

- Cooper, Emmanuel (2010). X Thousand Years of Pottery (quaternary ed.). Philadelphia: University of Pennsylvania Printing. ISBN978-0-8122-3554-8. OCLC 42475956.

- Cooper, Emmanuel (1989). A History of Earth Pottery. Chilton Volume Co. ISBN978-0-8019-7982-8.

- Howard, Coutts (2001). The Art of Ceramics: European Ceramic Blueprint 1500–1830. Yale University Press. ISBN978-0-300-08387-3. * Cox, Warren (1970). The volume of pottery and porcelain . Crown Publishers. ISBN978-0-517-53931-6.

- Dinsdale, Allen (1986). Pottery Science. Ellis Horwood, Ltd. ISBN978-0-470-20276-0.

- Dodd, Arthur (1994). Dictionary of Ceramics: Pottery, Glass, Vitreous Enamels, Refractories, Clay Building Materials, Cement and Concrete, Electroceramics, Special Ceramics. Maney Publishing. ISBN978-0-901716-56-9.

- Levin, Elaine (1988). The History of American Ceramics: From Pipkins and Bean Pots to Contemporary Forms, 1607 to the present. Harry N. Abrams. ISBN978-0-8109-1172-7.

- Perry, Barbara (1989). American Ceramics: The Collection of Everson Museum of Fine art . Rizzoli. ISBN978-0-8478-1025-3.

- Peterson, Susan (1996). The craft and art of clay . Woodstock, NY: The Overlook Press. ISBN978-0-87951-634-5. OCLC 604392596 – via Internet Archive.

- George, Savage; Newman, Harold (2000). Illustrated Dictionary of Ceramics. Thames & Hudson. ISBN978-0-500-27380-7.

External links [edit]

- Ceramic from the Victoria & Albert Museum

- Ceramic history for potters by Victor Bryant

- Index to the Metropolitan Museum Timeline of Art History – meet "ceramics" for many features

- Minneapolis Establish of Arts: Ceramics – The Fine art of Asia* Potweb Online catalogue & more from the Ashmolean Museum

- Stoke-on-Trent Museums – Ceramics Online

- Royal Dutch Ceramics

- United kingdom of great britain and northern ireland Ceramics Data – British Ceramic Brands

Source: https://en.wikipedia.org/wiki/Ceramic_art

0 Response to "Which of the Following Best Explains Why a Colorful Tulip Is Not Typically Viewed as a Work of Art"

إرسال تعليق